Weir’s Chief Strategy and Sustainability Officer Paula Cousins recently spoke at COP28 in the United Arab Emirates about the importance of harnessing innovative technologies to make mining more sustainable.

In a panel discussion hosted by the Ministry of Economy, Trade and Industry of Japan and moderated by the World Business Council for Sustainable Development (WBCSD), Cousins talked about a recent study that highlights a significant opportunity to reduce energy use and emissions in comminution.

The study is the first to utilise the WBCSD’s Avoided Emissions Guidance to examine mining processes and the results have been independently assured by SLR Consulting Limited.

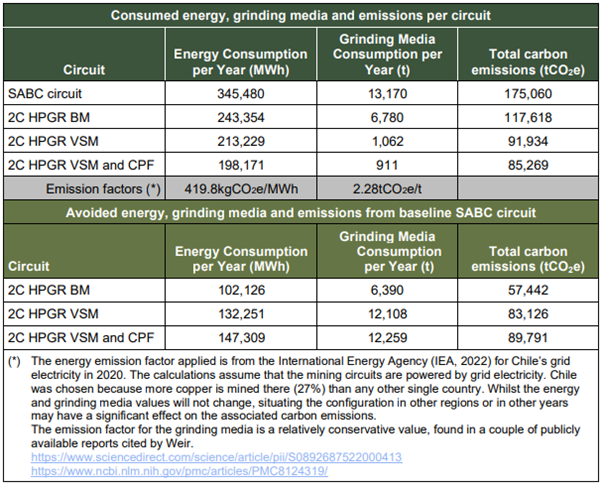

Three of Weir’s technology combinations were evaluated against a conventional comminution circuit design for an archetypal mine processing 15 million tonnes of copper ore per year in Chile.

Each circuit was based on a ‘rock to recovery’ system boundary – that’s to say, reducing rock direct from the mine to a size that enables the mineral to be recovered.

The four configurations were:

- Conventional comminution circuit based on a Semi-Autogenous Grinding (SAG) mill and ball mill.

- Weir’s Enduron® High Pressure Grinding Rolls (HPGR) replacing the SAG mill at the initial grinding stage.

- Enduron® HPGR, plus Swiss Tower Mills’ (STM) vertical stirred mill replacing the ball mill.

- Addition of a Eriez’s HydroFloat® coarse particle flotation (CPF) unit.

The study shows that replacing conventional technology with innovative new solutions can cut energy use by 40%, while also avoiding 50% of CO2e emissions.

The world needs more transition metals to achieve net zero, but the mining industry needs to extract these using significantly less energy and water, Cousins explained.

‘Our new, externally assured study highlights the potential for energy savings of 40% and for 50% of CO2e emissions to be avoided in comminution, the most energy intensive stage of mining processes,’ she said.

‘By adopting a systems-based approach to technology collaborations, we can help the mining industry scale up and clean up at the same time.’

The full results are published here:

Transformational Technologies

Comminution equipment doesn’t operate in a vacuum – it’s part of a wider and deeply interlinked mineral processing plant where the comminution circuit’s overall performance significantly influences mineral recovery.

Therefore, a holistic review of the overall circuit – from rock to recovery – is required.

These circuits are prone to increased feed variability, which requires the right combination of size reduction and classification equipment to minimise the fluctuation in product quality, as this enables greater efficiencies in the recovery circuit, explains Bjorn Dierx, Weir Minerals Global Product Manager Enduron® HPGR and Vertical Stirred Mills.

‘Enduron HPGRs can adapt to changing feeding conditions instantly because the roll speed and grinding force can be changed while in operation; as a result, the most effective, minimal stress-intensity force is applied to the particles to ensure they break at the given throughput rate,’ he said.

The STM mill has a vertical mill chamber, with grinding rotors (discs with castellations) installed on the central mill shaft. The mill feed is a slurry, pumped through the bottom of the mill and discharging from top. The mill chamber is filled with ceramic grinding media to approximately 60% of its volume.

The grinding media bed moves only in the horizontal plane, which ensures energy isn’t wasted. The vertical mill arrangement, combined with bottom feed entry and top discharge, ensures coarse particles don’t short-circuit the mill.

‘The grinding circuit that delivers the highest recovery and the lowest possible energy consumption is achieved by combining these two proven technologies. The Enduron HPGR prepares the feed for the two-stage STM vertical stirred mill grinding concept,’ Dierx said.

‘This grinding circuit is followed by Eriez’s HydroFloat CPF technology, which allows the use of a coarser, rougher grind size, delivering the operator additional reductions in grinding energy-requirements.’

The recovery or efficiency of conventional flotation is strongly related to the particle size of the ore.

‘Eriez’s HydroFloat CPF represents a major step forward in terms of recovery, by extending flotation efficiency over a size range that is two to three times greater than conventional flotation machines’ limit,’ Dierx said.